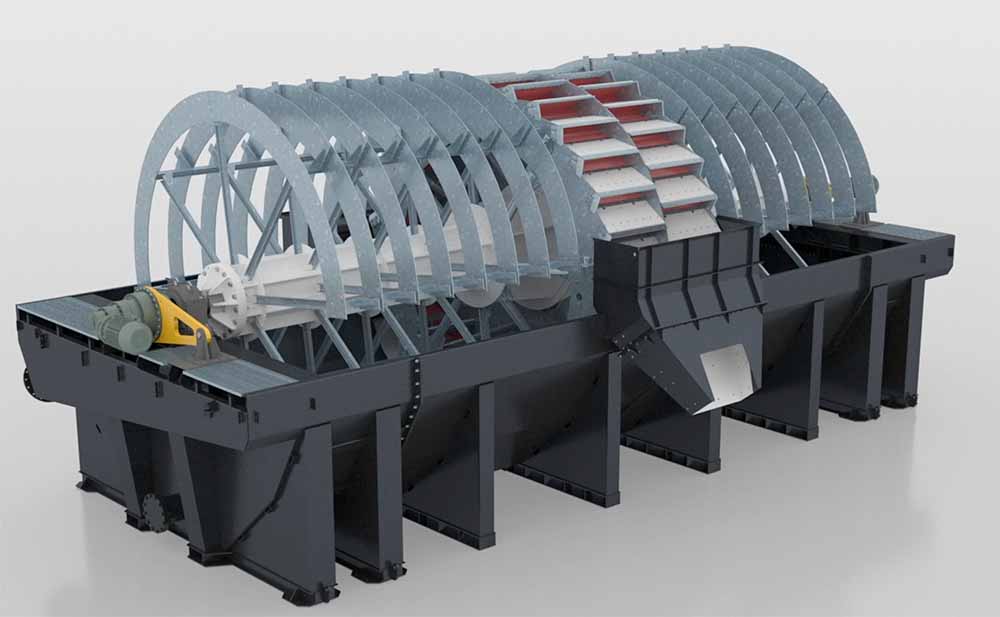

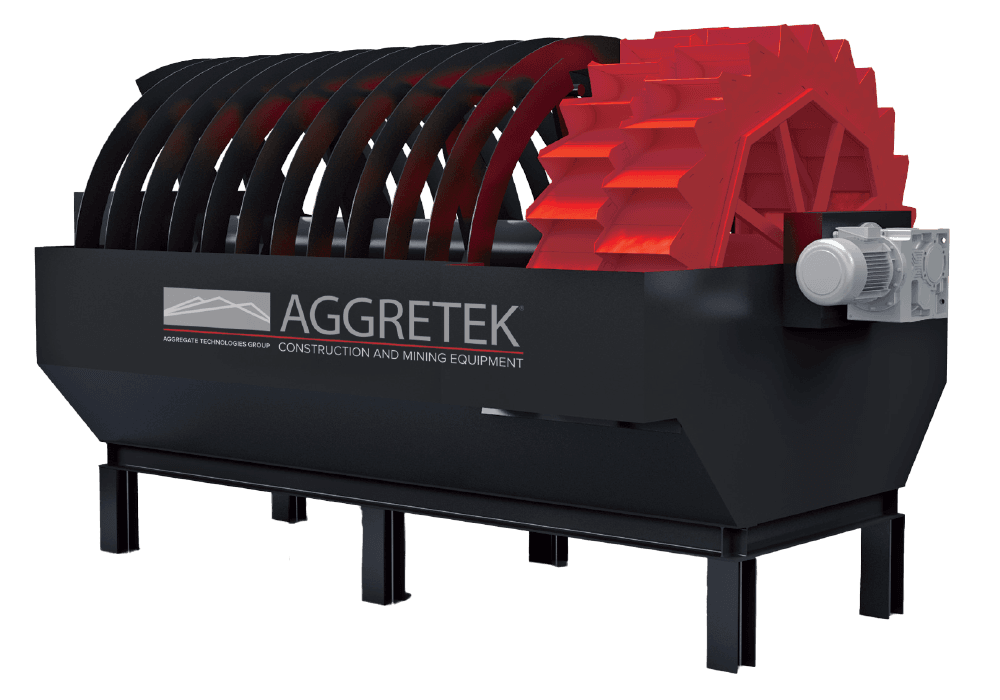

Bucket Wheel Dewatering Dredge

AGGRETEK Bucket Wheel range of sand classification systems are designed to operate with maximum versatility for efficient dewatering and fine sand recovery from the solid-water suspension in the underflow of a washing screen or dissolving station. The twin bucket units provide the removal of clays, silts and slimes to produce up to 2 grades of sand.

Excellent Fine Recovery

Sand from a washing screen becomes a solution with water and is fed into the bucket tank of the washer. Most of the course sand is taken away by the buckets, drained and discharged. The rest of this sand then floats in suspension to the auger tank. The courser of this sand, sinks to the bottom and is removed to the buckets for discharge by the auger screw. The silt,then floats away to the customers ponds. The water flow rate is an important factor, as a material with a high percentage of fines to be removed, will require a high volume of water.

BENEFITS

Bucket wheel dewaterers also boast a big decantation basin, providing great flexibility in control of feeding amount with feeding frequency control. An option for slow operating speed means a very low wear part cost, even for abrasive materials, as a low speed causes less friction and creates better results for fine material recovery. These features make the bucket wheel dewaterer one of the most cost-friendly solutions for washing applications.

IMPERIAL

ABW60

Drive (hp)

Water Consumption (gpm)

Capacity (stph)

Working (rpm)

ABW100

Drive (hp)

Water Consumption (gpm)

Capacity (stph)

Working (rpm)

ABW150

Drive (hp)

Water Consumption (gpm)

Capacity (stph)

Working (rpm)

METRIC

ABW60

Drive (kW)

Water Consumption (mT/hr)

Capacity (mtph)

Working (rpm)

ABW100

Drive (kW)

Water Consumption (mT/hr)

Capacity (mtph)

Working (rpm)

ABW150

Drive (kW)

Water Consumption (mT/hr)

Capacity (mtph)

Working (rpm)

Applications

- Gravel and concrete sand industries

- The production of industrial sand

- The treatment of polluted soils

- Rehabilitation of industrial sites

- Dredging of rivers or harbours, ect

Recovery

Can recover 1 or 2 grades of sand from a wet feed.

Maximum recovery of all material above 75 (200 mesh) providing major reduction in fine material dishcharging to the water management system, thus reducing recovery cycle and saving money.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900