HSI Crushers

HSI crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There are primary and secondary types of HSI crushers. Horizontal shaft impact (HSI) crushers are known for high reduction ratios, especially when processing soft and medium-hard materials. HSI’s are used in recycling, hard rock and soft materials.

High Performance For Higher Profitability

AGGRETEK AIH crushers, offering high reduction ratios, reduced power consumption, easier and safer maintenance are the solution for operating conditions where output and productivity demands are increasingly stringent.

The strength of AIH crushers makes them ideal for diverse applications and configurations. These crushers can replace large jaw crushers and be fed with material blocks the size of their feed opening.

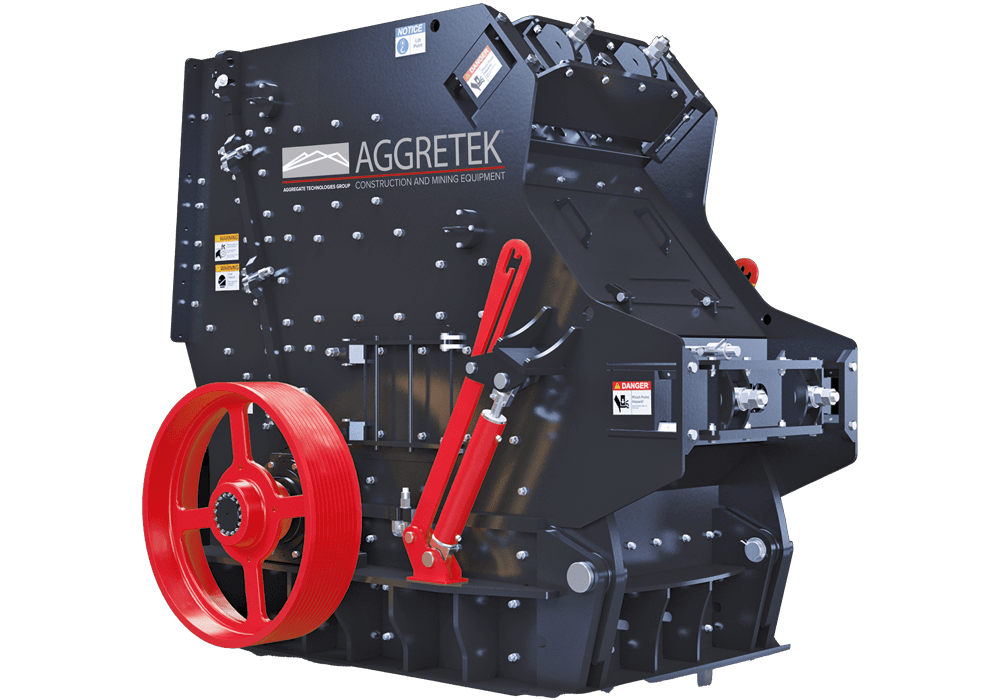

AIHP Series (Primary)

AGGRETEK AIHP crushers, offering high reduction ratios, reduced power consumption, easier and safer maintenance are the solution for operating conditions where output and productivity demands are increasingly stringent.

The strength of AIHP crushers makes them ideal for diverse applications and configurations. These crushers can replace large jaw crushers and be fed with material blocks the size of their feed opening.

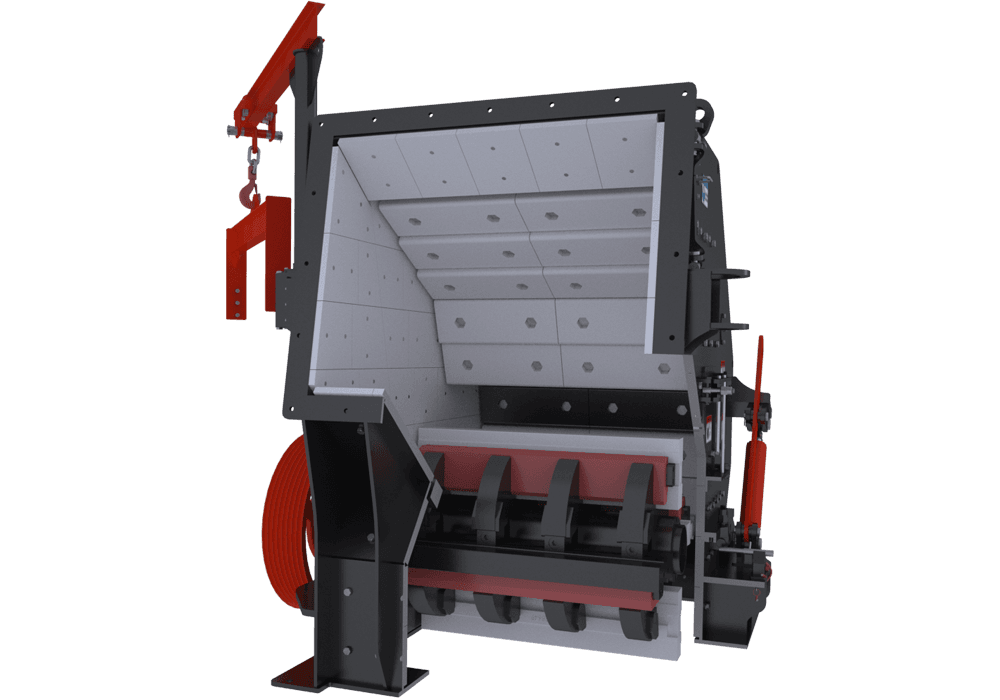

AIHT Series (Tertiary)

Designed for crushing soft and medium-hard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications. Adjustable and interchangeable breaker plates enable grinding up to 50 percent with a durable rotor that can operate in both directions, lowering overall operational and inventory costs of the machine.

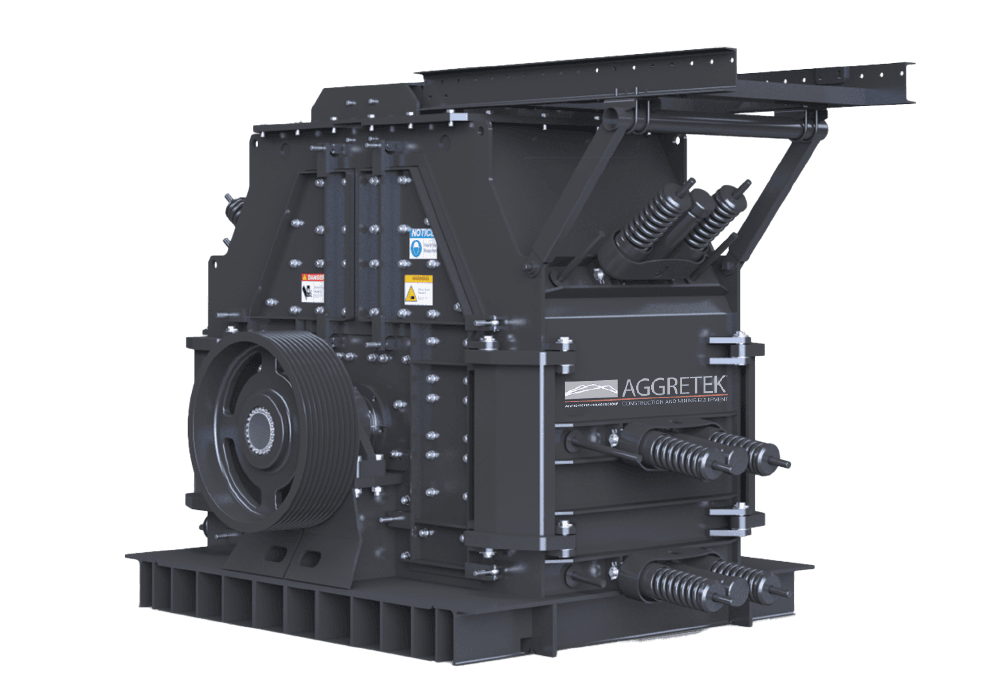

AIHS Series (Secondary)

With their high performance, high reduction percentages and perfect cubical-shaped final product, AGGRETEK secondary impact crushers are a great economical solution for crushing both medium-hard and hard materials such as river gravel, limestone and dolomite.The grinding type of AIH series impact crushers provide a very competitive design for the asphalt recycling process.

Crusher Features

CRUSHER BODY

Crusher main body is fabricated from low carbon steel. Crushing chamber is completely lined with thick, interchangeable, bolt-on abrasion resistant (AR) liners.

Sensors on the frame make maintenance interventions safer by preventing machine start up. Inspection doors located all around the frame make it possible to reach the interior of the Crusher.

WEAR PARTS

Enhanced solid wear parts and liners.

ROTOR

The quality of the dynamic rotor balance is G 6.3, according to ISO 1940/1

BEARINGS

High quality heavy-duty bearings, with bearing temperature sensors.

Models and Specifications

Primary Impact Crushers

AIHP1111

Rotor Diameter

inch

Rotor Width

inch

Capacity

stph

mtph

Power

HP

Weight

lbs

Primary Impact Crushers

AIHP1114

Rotor Diameter

inch

Rotor Width

inch

Capacity

stph

mtph

Power

HP

Weight

lbs

Primary Impact Crushers

AIHP1313

Rotor Diameter

inch

Rotor Width

inch

Capacity

stph

mtph

Power

HP

Weight

lbs

Primary Impact Crushers

AIHP1515

Rotor Diameter

inch

Rotor Width

inch

Capacity

stph

mtph

Power

HP

Weight

lbs

Primary Impact Crushers

AIHP1620

Rotor Diameter

inch

Rotor Width

inch

Capacity

stph

mtph

Power

HP

Weight

lbs

Secondary Impact Crushers

AIHS4440

Rotor Width

inch

Maximum Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

|

|

Secondary Impact Crushers

AIHS4448

Rotor Width

inch

Maximum Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

|

|

Secondary Impact Crushers

AIHS4459

Rotor Width

inch

Maximum Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

|

|

Secondary Impact Crushers

AIHS4840

Rotor Diameter

inch

Rotor Width

inch

Maximum Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

Secondary Impact Crushers

AIHS5148

Rotor Diameter

inch

Rotor Width

inch

Maximum Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

Secondary Impact Crushers

AIHS5159

Rotor Diameter

inch

Rotor Width

inch

Maximum Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

Tertiary Impact Crushers

AIHT4359

Rotor Diameter

inch

Rotor Width

inch

Max Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

Tertiary Impact Crushers

AIHT4340

Rotor Diameter

inch

Rotor Width

inch

Max Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

Tertiary Impact Crushers

AIHT4320

Rotor Diameter

inch

Rotor Width

inch

Max Feed Size

inch

mm

Capacity

stph

mtph

Power

HP

Weight

lbs

Primary Impact Crusher

Primary Impact Crushers are preferred for their high performance and high reduction ratios in crushing soft-character substances like gypsum and limestone. Due to the different principle of crushing these materials, the reduction ratio is higher than in Jaw Crushers.

Secondary Impact Crushers

With their high performance, high reduction percentages and perfect cubical-shaped final product, AGGRETEK secondary impact crushers are a great economical solution for crushing both medium-hard and hard materials such as river gravel, limestone and dolomite.

Tertiary Impact Crusher

Designed for crushing soft and medium-hard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications. Adjustable and interchangeable breaker plates enable grinding up to 50 percent with a durable rotor that can operate in both directions, lowering overall operational and inventory costs of the machine.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900