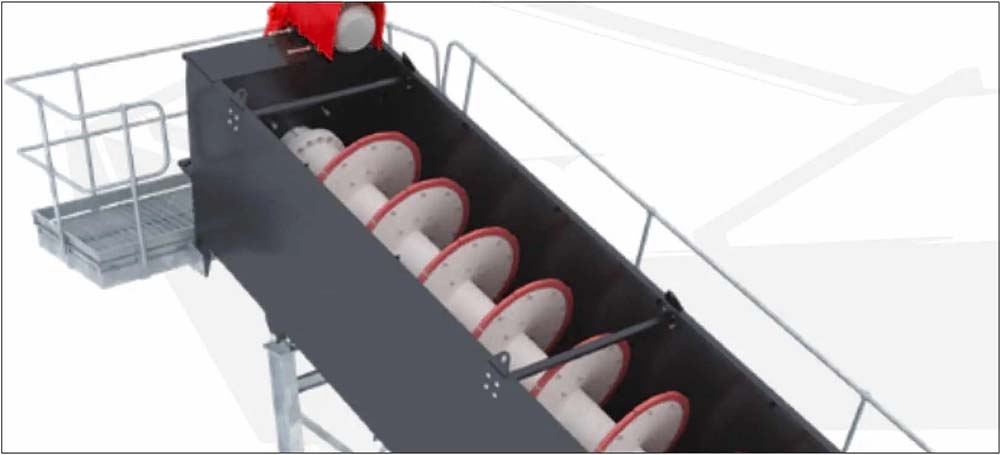

Coarse Material Washers

Coarse material washers are used to remove a limited amount of dirty material from a coarse aggregate. This material includes very water soluble slimes, silts, soft clay, and organic particles. They are often used as a final wash following a wet screen and are designed to scrub and clean gravel and crushed stone up to 75mm (3’’) in size. Both single and double spiral units are available depending on the capacity required.

Effective Washing Of Natural And Crushed Materials

Capable of producing high capacities, coarse material washers deliver extreme productivity. High efficiency single or dual drives result in low power requirement, thus reducing operating costs while increasing throughput. A large capacity pool and adjustable speed control via sheave changes ensures a steady and consistent flow of fine aggregate products.

Available in both single and twin screw configurations.

High efficiency single or dual drives result in low power requirement, thus reducing operating costs while increasing throughput. A large capacity pool and adjustable speed control via sheave changes ensures a steady and consistent flow of fine aggregate products.

More Features

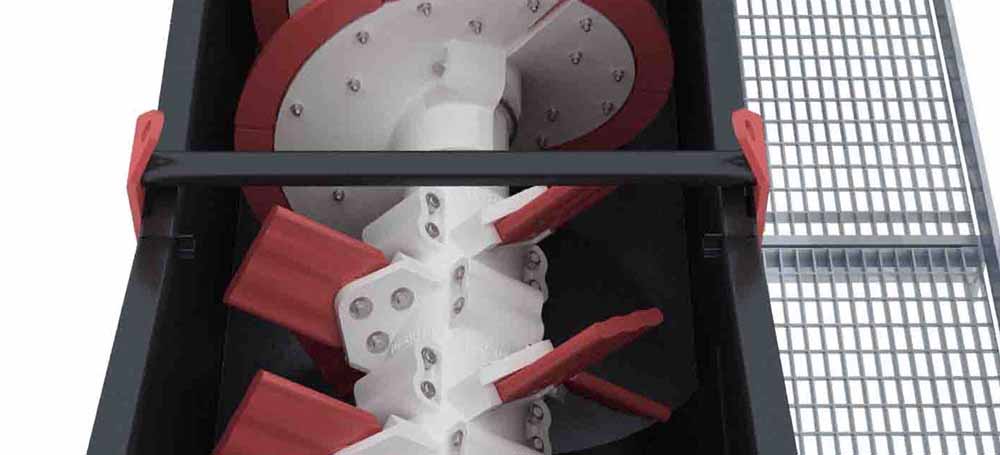

- Heavy duty steel plate construction provides years of operation

- Oil lubricated heavy duty gear box

- Standard polyurethane, NiHARD or steel backed rubber flights

- Simple parts replace-ment assemblies

- Easy access outboard lower bearing assemblies

- Full stairs, legs and service platforms standard

IMPERIAL

Size (DIA x L)

inch x feet

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Max Capacity

stph

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Max Capacity

inch

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Power Required

hp

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Screw

rpm

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Weight

lbs

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

METRIC

Size (DIA x L)

mm

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Max Capacity

mtph

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Max Capacity

inch

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Power Required

kW

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Screw

rpm

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Weight

kg

SINGLE

ACWS3618

ACWS4420

DOUBLE

ACWD3618

ACWD4420

Outboard LBA

Minimizes or eliminates water and material contamination of the bearings due to seal wear.

Single or Twin Drives

High efficiency drives result in low power requirement, thus reducing operating cost while increasing throughput.

Oil lubricated heavy duty gearbox

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900