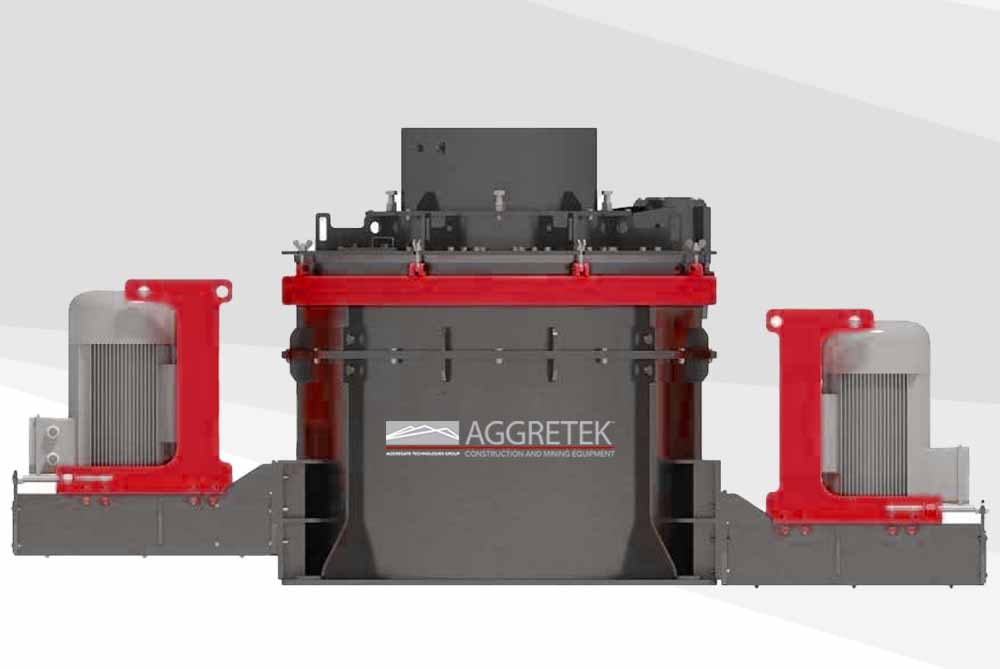

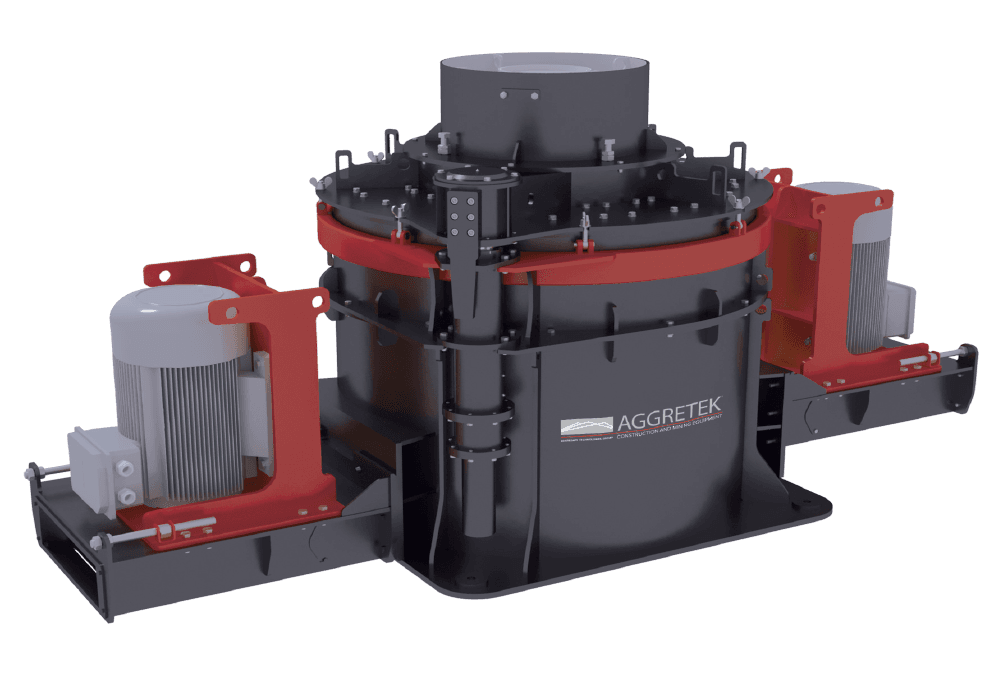

VSI Crushers

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. These crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone from aggregate.

Exceptional Minerals Beneficiation Capabilities

Impact crushing occurs on anvil. This type of crushing is recommended for non abbrasive or love abrasive materials, such as limestone, in secondary and tertiary crushing applications with larger feed sizes. Selective crushing of moderately abrasive slags, inustrial minerals, mining overburden ect. High capacity production of cubical and high quality sand can be obtained.

VSI APPLICATIONS

Rock and mineral deposits vary widely from site to site, country to country, and around the world. Crushing plants, circuit variations, and product requirements are infinite. For this reason, any crusher, if it is to suceed, perform reliably and economically, it must be designed to fit the specific needs of your job.

Fully welded construction, Large receiving hopper, heavy duty main pedestal, drop in style, oil lubricated bearing assembly having ample dimensioned spherical roller bearings

Hydraulic lid lifter mechanism

Externally adjustable feed tube system with a convenient inspection door mounted on the lid, provides safe and easy inspection

Lid and main frame protection with special alloy wear resistant liners

Advanced alternatives with open table designs, multi-port rotor and large bearings are the main reasons for our crushers to provide high value solutions and deliver high performance.

Models and Specifications

IMPERIAL

Vertical Shaft Impact Crushers

Maximum Feed Size

inch

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Power

HP

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Speed

rpm

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Max. Capacity

stph

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Max. Capacity

mtph

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Weight

lbs

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

METRIC

Vertical Shaft Impact Crushers

Maximum Feed Size

mm

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Power

kW

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Speed

rpm

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Max. Capacity

stph

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Max. Capacity

mtph

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

Vertical Shaft Impact Crushers

Weight

kg

AIV955/ROR

Single Drive

AIV95D/ROR

Dual Drive

AIV955/ROS

Single Drive

AIV95D/ROS

Dual Drive

AIV95S/SOS

Single Drive

AIV95S/SOS

Dual Drive

ROCK ON ROCK (ROR)

ROR configurations are recommended when crushing the most abrasive materials, in tertiary and quaternary applications where additional fines production is desired.

Autogenous crushing occurs inside crusher chamber between material thrown from rotor and material resting on rock shelf or material springing back from rock shelf.

Production of cubical high quality aggregates and sand from highly abrasive input materials, such as gravel, granite, quartzite etc

Crushing of highly abrasives materials, such as aluminum oxide, ferrosilicon, abrasives, glass etc

Selective crushing of slags from steel mills, waste incineration plants etc.

ROCK ON STEEL (ROS)

Impact crushing on anvils and also autogenous crushing between material springing back from anvils and material thrown from rotor occurs at the same time.

This type of crushing is recommended for low and medium abrasive materials such as gravel, limestone, dolomite, diabase, bricks, cement clinker etc

Production of cubical and high quality sand can be achieved.

Additional fine production can be obtained with higher rotor speeds.

Selective crushing of conglomerates, moderately abrasive slags, industrial minerals, mining overburden etc

Recycling

STEEL ON STEEL (SOS)

Impact crushing occurs on anvil.

This type of crushing is recommended for non abbrasive or low abrasive materials, such as limestone, in secondary and tertiary crushing applications with larger feed sizes.

Selective crushing of moderately abrasive slags, industrial minerals, mining overburden etc.

High capacity production of cubical and high quality sand can be obtained.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900