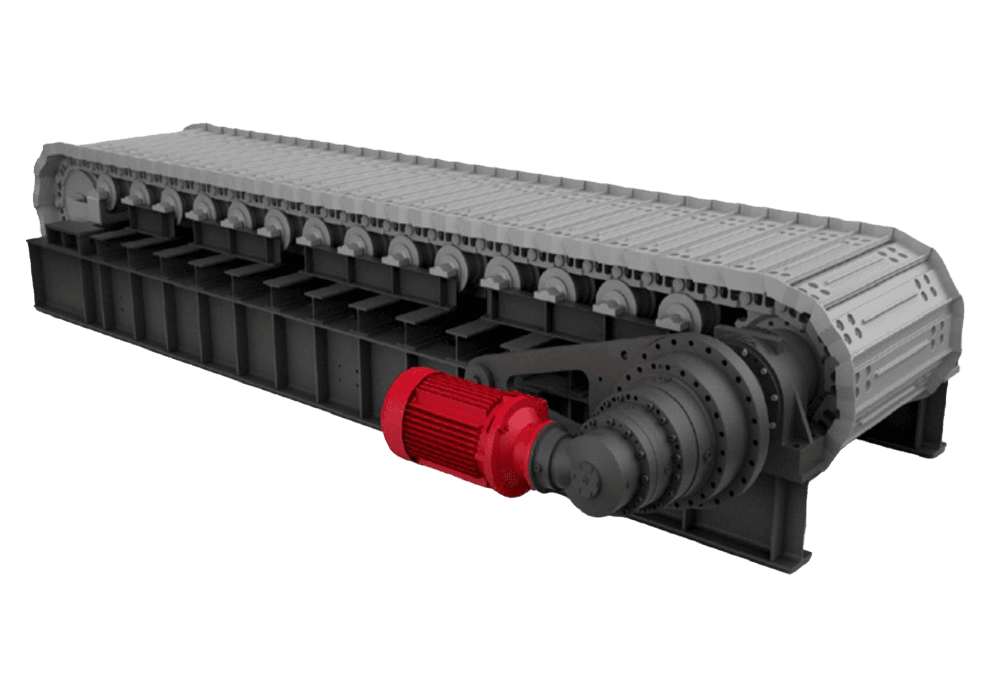

Apron Feeders

AGGRETEK Apron Feeders are made of rugged, heavy duty construction and designed to handle large lumps and where no fines removal is required or where fines are removed by a separate Scalper. When the feed material is wet, sticky or clay like, the Apron Feeder is the machine to select. Generally, the Apron Feeder can be installed in a horizontal or inclined position. The high inclination also allows to build compact installations and to reduce the length of the Apron Feeder keeping the investment costs low.

Why AGGRETEK Apron Feeders

Our Apron Feeders are made of rugged, heavy duty construction and designed to handle large feed sizes and where no fines removal is required or where fines are removed by a separate Grizzly Scalper.

HEAD DRIVE SHAFT

The sprockets are of the bolt on segmental type made from wear resisting alloy steel. They are designed with an odd number of teeth which increases the life of the sprocket because contact with the teeth is only completed after two revolutions. The sprockets are bolted onto keyed on hubs.

FRAME

Rugged welded construction frame to provide rigid support for intense loading conditions. Full length beams manufactured from rolled steel joists form the top and bottom members of this one piece unit. Crossmembers tie the framework together for maximum strength. Bolted onto these crossmembers are the universal beams which carry the impact rails and the carrier rolls. For ease of removing the carrier rolls, the outside carrier roll channels are sectionalized and bolted to the cross beams.

CHAIN

Crawler tractor type track chains, sealed and lifetime lubricated, are used on all AGGRETEK Apron Feeders. The pins and bushes are all made from heat treated alloy steel and hardened on the wearing surfaces. The chain links are drop forged for increased carrying capacity and strength. The chains can be adjusted by means of a threaded screwed take-up arrangement. Hydraulic ram adjustment is available as an option.

BEARINGS

Anti-friction spherical roller bearings are fitted to the head and tail shafts and housed in heavy duty plummer blocks. Bearings are grease lubricated and a grease reservoir is included in the design of the bearing housings and end caps. The Apron Feeder has a remote mounted electrically operated automatic greasing system as standard.

TAIL TRACTION WHEELS

Cast steel traction wheels are lighter duty as they act purely as a directional guide to centralise the track. Long service life can be expected as there is minimal load carried on the traction wheels. as a directional guide to centralise the track. Long service life can be expected as there is minimal load carried on the traction wheels. steel.

AAF4815

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

AAF4818

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

AAF4826

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

AAF6015

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

AAF6018

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

AAF6026

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

AAF7226

Capacity / Chain Speed

feet

mm

13 ft/min

stph

mtph

18 ft/min

stph

mtph

20 ft/min

stph

mtph

26 ft/min

stph

mtph

Rugged Heavy Duty Construction

An apron feeder is run at very low speeds and at a controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a front-end loader and is ideal for withdrawing material from under a stockpile or from uner a primary crusher.

Low Maintenance

AGGRETEK’s heavy duty and rubust apron feeders are engineered and built with an intense commitment to quality and attention to detail, providing maximum uptime and many years of service life. Because of their durable, long life components, our apron feeders are low maintenance even under severe conditions.

Optional Dribble Conveyor

As an optional extra, AGGRETEK Apron Feeders can incorporate a Dribble Conveyor which is located under the feeder to catch the small pieces, fines and lumps of material that became trapped on the feed side of the apron pans and dribble out on the return side. This feature eliminates manual clean up and saves on man hours.

CARRYING ROLLERS

The carrying rollers are standard tractor type featuring a hardened and ground shaft fitted with a centre thrust shoulder and hardened roller. The sleeve bearings on the carrying roller takes high impact loads and, with the duo-clone seals providing lifetime lubrication an extended wear life can be assured. Closely spaced along the length of the Feeder, smooth travel of deck during operation is maintained.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900