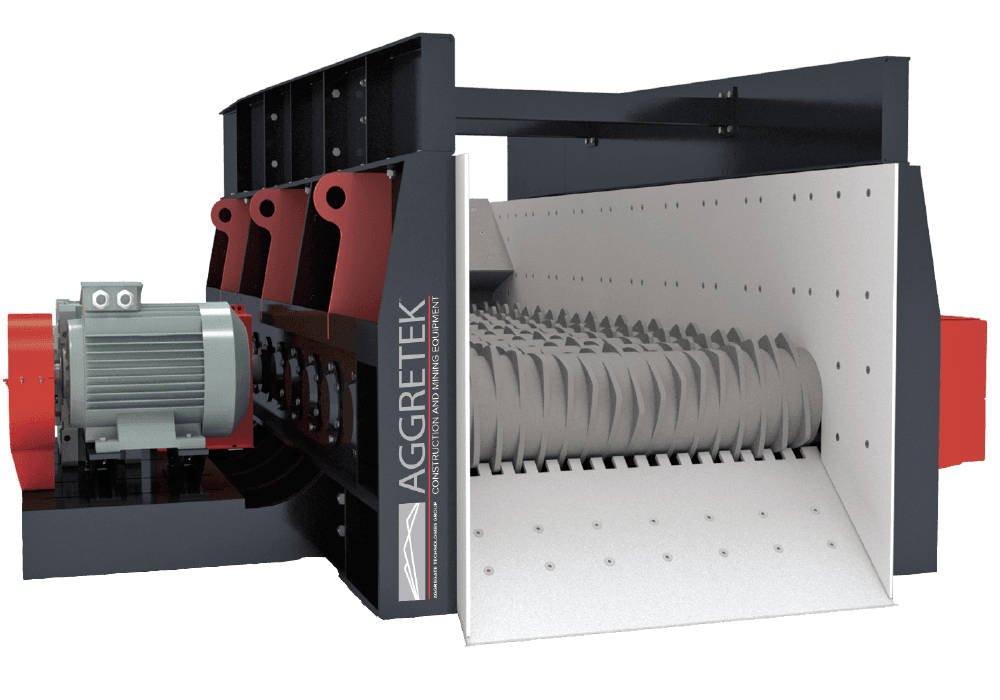

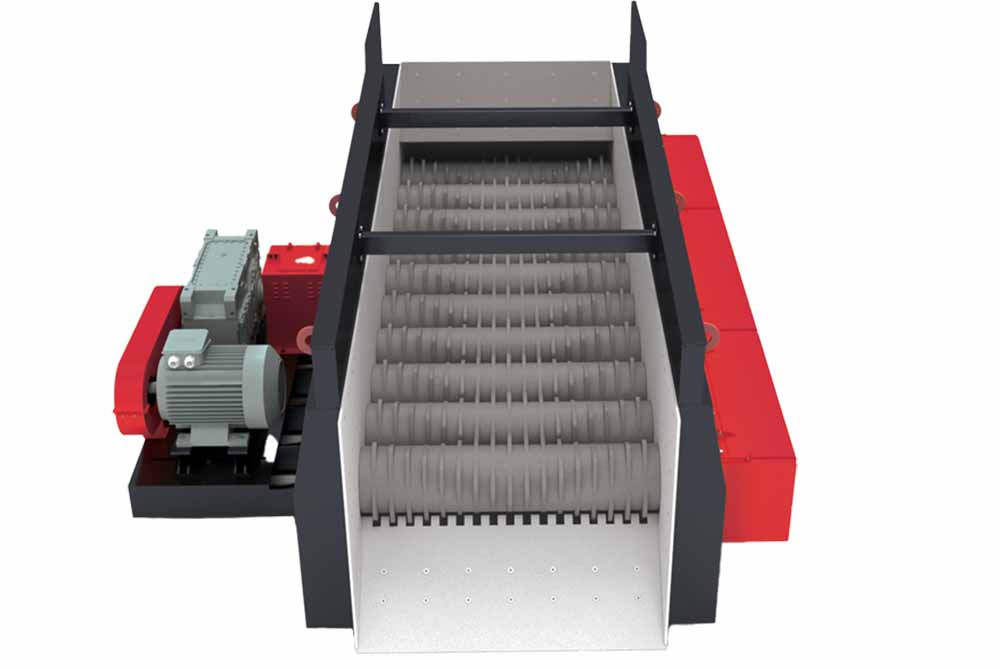

Wobbler Feeders

In cases of difficult to screen, wet, sticky bulk materials this kind of feeding and scalping distinctly outclasses the traditional screening machines, which frequently show baking and adhesions with these materials. The positive action of the rotating triangular bars causes material to tumble forward assuring separation of fines and a uniform feed rate. In heavy duty, high capacity applications, the wobbler is often fed from a heavy duty apron feeder.

Scalping Out Fines And Feeding Only Oversize To The Crusher

The Wobbler Feeder consists of a frame, triangular bars and a chain drive system used to rotate the bars. The transmission is driven by an electric motor, a reduction gear unit and a series of chains with oil bath lubrication. The drive system connects all the bars with a single or double strand chain that attaches to sprockets on each bar. This maintains the gap, or opening, between the bars at the same dimension throughout the bar rotation. The triangular or circular shafts with self-cleaning disc rotate synchronously to each other and fine materials, sludge fragments and waste materials that are not required to enter the main crusher fall down through the opening defined in the design by gravity.

COMPACT DESIGN

The compact design, resulting from the horizontal material flow, as well as a multitude of options permit the application in many ranges, above as well as underground

PROVEN QUALITY VIBRATORS

The vibrators used on our feeders are of internationally approved quality, and serve to increase feeder performance to the highest level. The frequency of these vibrators is adjustable through the control panel, making it very easy to maintain the grizzly feeder’s performance at peak levels according to the nature of the rock being crushed.

AFW3911

W x L

inch x feet

mm

Drive

HP

kW

Capacity

stph

mtph

AFW4711

W x L

inch x feet

mm

Drive

HP

kW

Capacity

stph

mtph

AFW5513

W x L

inch x feet

mm

Drive

HP

kW

Capacity

stph

mtph

AFW6313

W x L

inch x feet

mm

Drive

HP

kW

Capacity

stph

mtph

AFW6316

W x L

inch x feet

mm

Drive

HP

kW

Capacity

stph

mtph

AFW7216

W x L

inch x feet

mm

Drive

HP

kW

Capacity

stph

mtph

Safe to Operate

AGGRETEK Wobbler Feeders operate without generating dust, vibration, or loud noise and with low energy consumption, also reduces work safety and environmental risks, ensures trouble-free feeding of especially high moist and sticky materials thanks to its long disc life and long service life.

Low Maintenace

AGGRETEK Wobbler Feeders are self-cleaning and designed to resist clogging and reduce blinding.

They also feature an automatic lubrication system and bars are manufactured from cast wear metal, providing a much longer service life than plate style bars.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900