Jaw Crushers

AGGRETEK Jaw Crushers are designed for applications where cost-efficient primary reduction of hard, abrasive materials is concerned. Representing the highest technical and manufacturing knowledge, our heavy duty crushers match the most arduous crushing conditions encountered.

Maximum Crushing Power

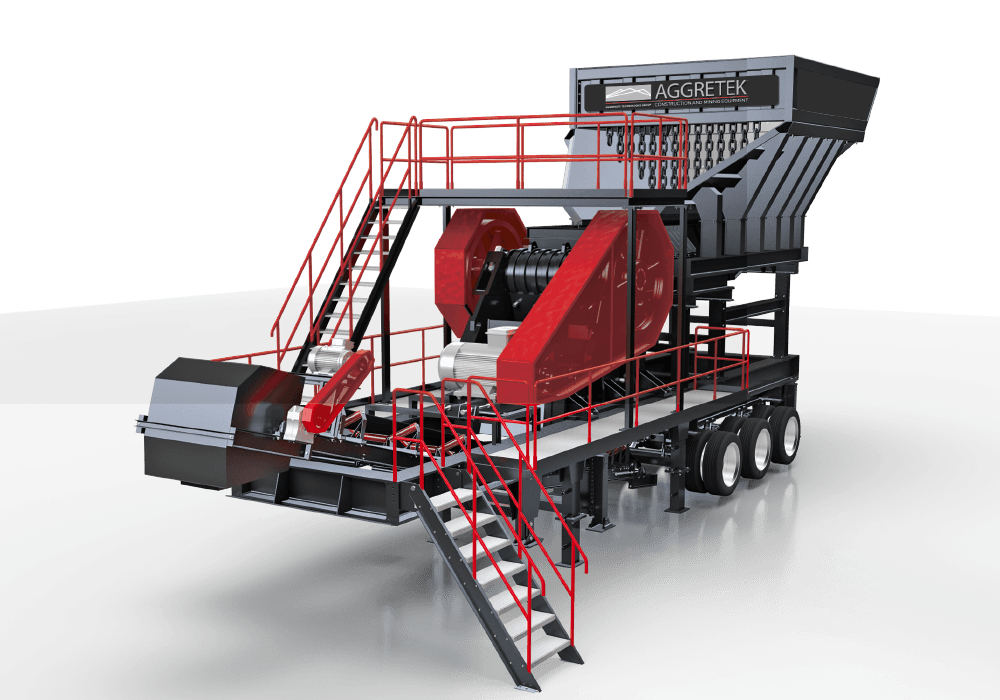

Temporary aggregate production is very common for short-term projects like road and dam construction. Since most of the time the equipment is moved out of the temporary quarry, disassembly, transportation and installation expenses add extra costs that can be just as significant as the start-up investment itself. In such cases, despite higher initial investment costs, mobile crushing and screening solutions are better options than stationary ones because of the time-saving disassembly, transportation and installation advantages they provide.

Shaft & Bearings

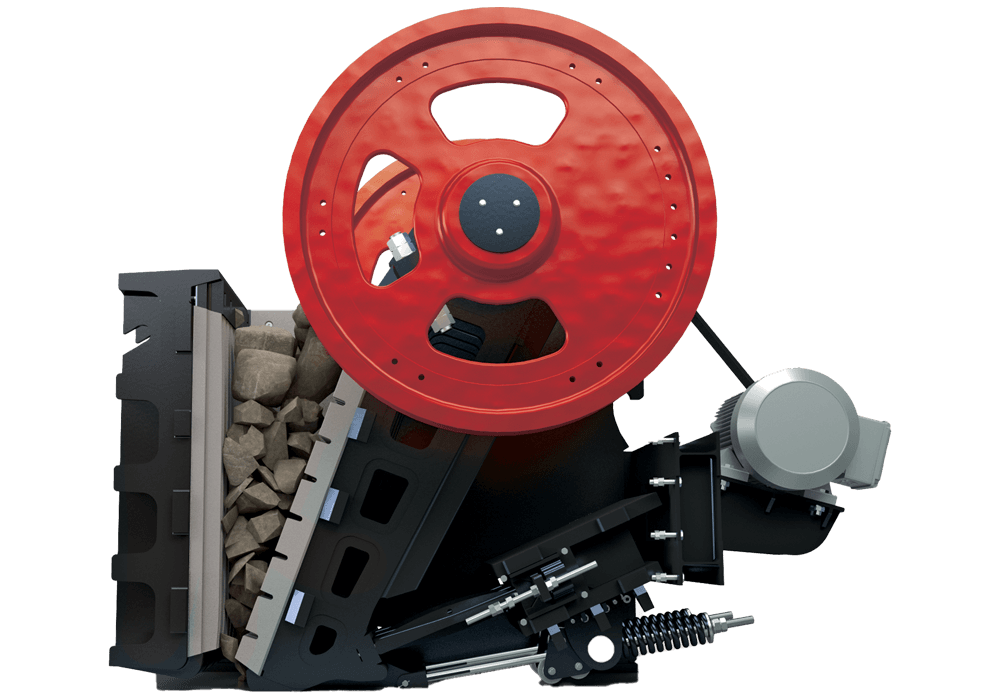

The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate.

Crushing Power

Wide range of crushing for soft to very hard materials. For various materials, crushing efficiency is increased by different jaw types.

Adjustment

The closed side setting can be adjusted using shim plates with hydraulic power.

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling.

Typical applications for jaw crushers are;

- Ore Mining

- Rock Quarries

- Sand and Gravel

- Construction aggregates

- Recycled concrete (concrete, asphalt, etc.)

- Industrial Applications (slag, anodes, metallurgy, chemical industries etc.)

Side Liners

Reversable high manganese cast steel jaw plates. Different profiles are available for different rock types.

Toggle Plate

The optimal-angle toggle plate generates extra crushing force and at the same time provides security for the drive system.

Models and Specifications

IMPERIAL

Primary Jaw

ACJ1524

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ2232

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ2636

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ3040

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ3444

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ3750

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ4355

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Primary Jaw

ACJ4763

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Secondary Jaw Crushers

ACJ1035

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Secondary Jaw Crushers

ACJ1443

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

Secondary Jaw Crushers

ACJ2655

Feed Opening L x W

inch x inch

Power

HP

Capacity

stph

Weight

lbs

METRIC

Primary Jaw

ACJ1524

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ2232

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ2636

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ3040

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ3444

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ3750

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ4355

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Primary Jaw

ACJ4763

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Secondary Jaw Crushers

ACJ1035

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Secondary Jaw Crushers

ACJ1443

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Secondary Jaw Crushers

ACJ2655

Feed Opening L x W

mm

Power

kW

Capacity

mtph

Weight

kg

Flywheel

Large diameter, heavy flywheels provide the necessary inertia for crushing the hardest of materials while minimizing vibration resulting in smooth running operation. Flywheel hubs of our jaw crushers are equipped with special locking assembly which connects flywheels to the eccentric shaft. This system ensures that the flywheel is held safely and tightly on the shaft. This feature is important as the crusher has to be brought into operation under load, resulting from unforeseen stoppages.

Main Shaft

Forged from hardened and tempered alloy steel (chrome-moly-nickel) with particularly large diameters to suit heavy-duty applications, and can withstand extreme temperatures. High fatigue resistance due to a fine finish and the elimination of screw threads and sharp radii which can contribute to stress concentrations.

Cast steel and precision machined

The pitman is made of high-quality cast steel and is pro- pelled by two massive cast steel or iron flywheels. A very large eccentric shaft and four large spherical roller bear- ings ensure the greatest reliability even under the most se- vere crushing conditions. The grease-lubricated bearings are kept free from contamination by means of well-prov- en labyrinth seals.Cast steel pitman is designed for easy maintenance and can be removed from the frame as an assembly.

Bearings

Bearings are grease-lubricated and have grease- filled labyrinth dust seals to protect the bearings from dust and water.

The single piece cast steel frame bearing housings ensure a perfect fit to the crusher frame. They also prevent unnecessary loads to the frame bearings. Side bearings are mounted in removable housings for easier maintenance.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900